Lg Lsxc22386 Page 43

Workshop Manuals

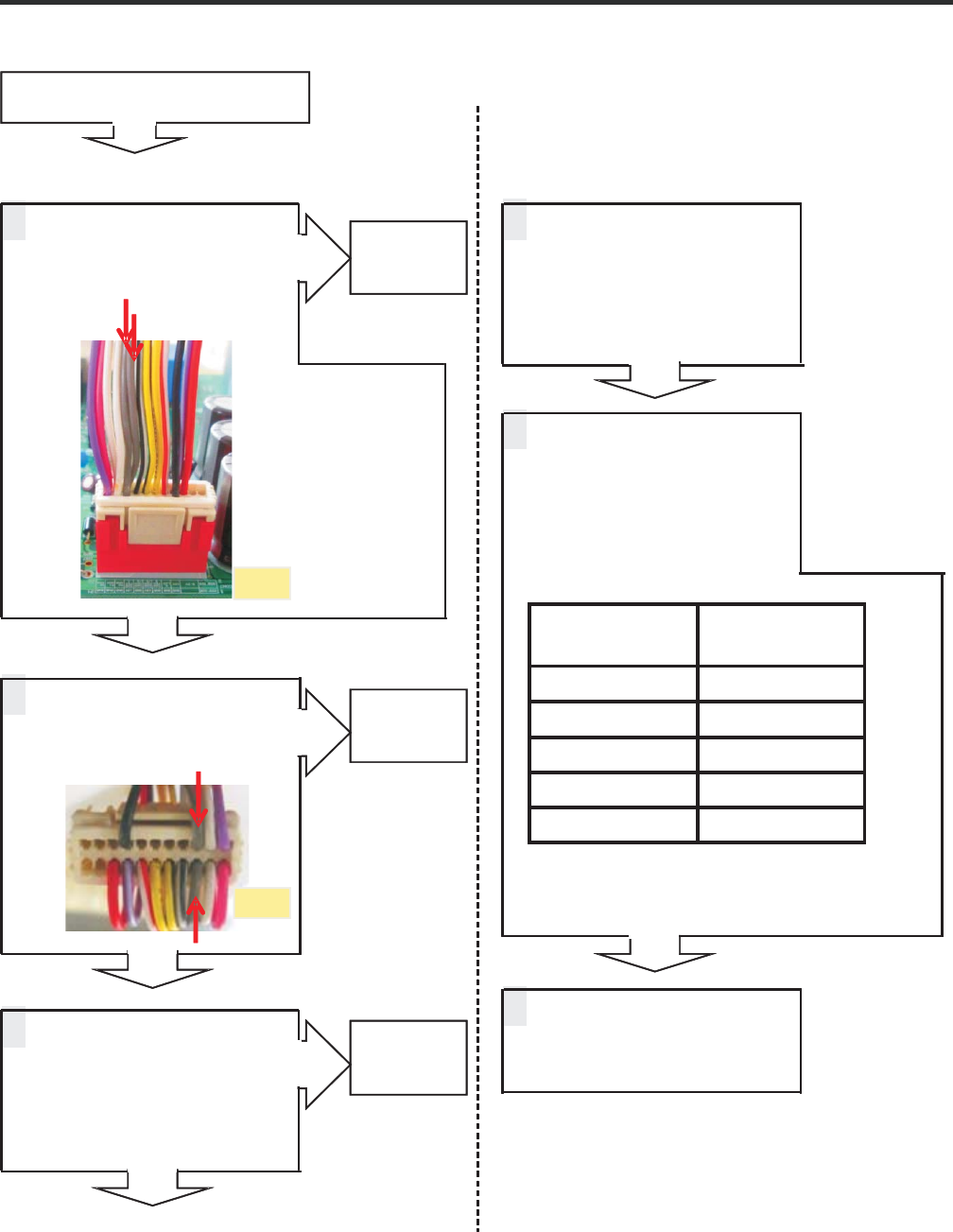

Troubleshooting

Refrigerator Sensor Error ( E r2)

1

Reconnect or

repair the

connector

Is the Connector disconnected

or loose between Main PCB and

sensor?

Yes

No

3

Check the Sensor resistance.

Is resistance OFF (Sensor open)?

Yes

No

Replace the

refrigerator

4

Check the Sensor resistance.

Is resistance normal?

Yes

5

Check the Temperature and

resistance refer to the table.

No problem?

Yes

6

Explain to customer

CON7

17

th

pin ~ 18

th

pin

Resistance [Ω]

23ºF / -5ºC 38k

32ºF / 0ºC 30k

41ºF / 5ºC 24k

50ºF / 10ºC 19.5k

59ºF / 15ºC 16k

CON7

2

Check the Sensor resistance.

Is resistance 0Ω (Sensor short)?

Yes

No

Change the

Sensor

CON7

43

Contents Summary of Lg Lsxc22386

- Page 1REFRIGERATOR SERVICE MANUAL CAUTION PLEASE READ CAREFULLY THE SAFETY PRECAUTIONS OF THIS MANUAL BEFORE CHECKING OR OPERATING THE REFRIGERATOR. MODELS: LSXC22386 * LSXC22326 * LSXC22336 *�

- Page 2CONTENTS SAFETY PRECAUTIONS ............................................................................................................................3 1. PRODUCT STANDARD ..........................................................................................................................8 4

- Page 3Safety Warning and Cautions Chapter 1 Safety Warning and Cautions ► Observing cautions for safety can prevent accidents and dangers. ► Cautions are classified into Warning and Caution and the meanings are as follows WARNING WARNING indicates the possibility of serious injury or death if the instruct

- Page 4Safety Warning and Cautions WARNING If grounding is required, be sure to Do not store poisonous, consult an electrician. flammable, or explosive chemicals The refrigerator in the refrigerator. must be plugged in to a properly rated There is danger of and grounded explosion and fire. Grounding nut ou

- Page 5Safety Warning and Cautions WARNING Do not alter the power cord. Do not place heavy objects on the Replace it only with an exact factory refrigerator. replacement part. Falling objects when Electric shock or opening or closing doors fire may occur may cause injury. due to electrical damage of power

- Page 6Safety Warning and Cautions WARNING Do put the vessel that flower base, Do not accumulate objects on a cup, cosmetics or drugs, etc refrigerator or do not keep are contained on the foods in random method. refrigerator. Dropping of objects when opening Fire or electric shock may occur, or or closing

- Page 7Safety Warning and Cautions WARNING power plugs catching with the end Do not use power cords or power of plugs without catching cords. plugs when they are damaged or Fire may occur due to electric holes of power plugs are loose. shock or short-circuit. Fire may occur due to electric shock or short-c

- Page 8Product Standards Model LSXC22386* LSXC22326* LSXC22336* Total inner capacity(L) 615.40L (21.7 Cu.ft) 619.80L (21.9 Cu.ft) Effective inner F-Room 209.40L (7.40 Cu.ft) 209.40L (7.4 Cu.ft) capacity R-Room 406.00L (14.30 Cu.ft) 410.40L (14.50 Cu.ft) Outer dimension ( W X D X H ) 35 8/9" x 31 4/5" x 70

- Page 9Circuit Diagram 9�

- Page 10Specifications 1. Specifications Unit : inch (mm) Model LSXC22386* / LSXC22326* / LSXC22336* ltem Width (A) 35.9 (912) Width When opening door by 90° (including handle) (B) 39.6 (1005) Case (including back handle) (C) 24.6 (624) After disassembling door (including hinge, L) (D) 27.3 (694) Depth Incl

- Page 11Appearance Size of Refrigerator and Name of Every Part 2. Main Name MODEL : LSXC22386* Freezer Refrigerator Compartment Compartment LED Lamp Dairy Corner Filter LED Lamp Automatic Icemaker Shelf Shelf Refreshment center Shelf Door Bin Freezing Zone Fresh zone Door Bin Door Bin 11�

- Page 12Appearance Size of Refrigerator and Name of Every Part 2. Main Name MODEL : LSXC22326* / LSXC22336* Freezer Refrigerator Compartment Compartment LED Lamp Dairy Corner Filter LED Lamp Automatic Icemaker Door Bin Shelf Shelf Shelf Door Bin Door Bin Door Bin Freezing Zone Fresh zone Door Bin Door Bin 1

- Page 13Micom Function 1. Operating Panel MODEL : LSXC22386* Ice Type Refrigerator Dispenser Selection Button Temperature adjustment button for refrigerator compartment Freezer Temperature Ice Plus adjustment button Ice on / off for freezer Ice Plus compartment button(1sec) Ice Making ON / Light / OFF(3secs

- Page 14Micom Function 1. Operating Panel MODEL : LSXC22386* / LSXC22326* / LSXC22336* Ice Type Refrigerator Dispenser Selection Button Temperature adjustment button for refrigerator compartment Freezer Temperature Ice Plus adjustment button Ice on / off for freezer Ice Plus compartment button(1sec) Ice Mak

- Page 15Micom Function 2. Function description 2-1. Funnction of Temperature Selection Power Notch Temp 1st press 2nd press 3rd press 4th press 5th press 6th press 7th press 8th press 9th press 10th press 11th press 12th press 13th press Initiallly On Freezer °F 0 -1 -2 -3 -4 -6 8 6 5 4 3 2 1 0 Refrigeratio

- Page 16Micom Function 2-5. Control of variable type of freezing room fan 1. To increase cooling speed and load response speed, MICOM variably controls freezing room fan motor at the high speed of RPM and standard RPM. 2. MICOM only operates in the input of initial power or special freezing operation or loa

- Page 17Micom Function 2-10. Function of Trouble Diagnosis(88-LED) 1. Failure diagnosis function is function to facilitate service when nonconforming matters affecting performance of product during use of product. 2. In occurrence of failure, pressing the function adjustment button does not perform function

- Page 18Micom Function 2-11. Test Function 1. Test function is function to find out any failed part in the failure status or check function of PWB and the product. 2. The test button is placed on the main PCB (test switch) of the refrigerator. The refrigerator ends the test mode after Max. 2 hours irrespect

- Page 19Micom Function 2-13 Ice on / off function Press Ice on/off Button to select Ice Making on or off. Ice on Mode in factory default setting. Ice on Ice on / off BUTTON Ice off Ice on / off BUTTON 19�

- Page 20Icemaker and dispenser working principles and repair 1. OPERATION PRINCIPLE 1-1. Operation Principle of Icemaker Power On Start Position • Adjusts EJECTOR to Start Position with power on. Icemaking Mode • Waits until water becomes cold after starting the icemaking operation. Checking full ice Mode •

- Page 21Icemaker and dispenser working principles and repair 2. Function TEST 1. CAUTION! Before you carry out the test mode, check whether the water is frozen in the icemaker completely. If the test is performed while the water is not frozen in the icemaker, The water may overflow after test and it will ca

- Page 22Micom Circuit description 1. Refrigerator undercool/overcool compensation circuit Temperature compensation from cut JCR1 +1 +2 JCR2 +1 JCR3 -1 -2 JCR4 -1 Undercool compensation Overcool compensation Refrigerator temperature compensation Remarks JCR3 JCR4 JCR1 JCR2 0 (Factory default) CUT -1 CUT -1 C

- Page 23Micom Circuit description 2. Freezer undercool compensation circuit Temperature compensation from cut JCF3 -1 -2 JCF4 -1 Undercool compensation Freezer temperature Remarks JCF3 JCF4 compensation 0 (Factory default) CUT -1 CUT -1 CUT CUT -2 ►Above option circuit compensates the freezer temperature by

- Page 24Micom Circuit description 3. Table of sensor resistance characteristics Refrigerator sensor 1, 2, defrost Measured temperature Freezer sensor sensor, external sensor -20 22.3kΩ 77kΩ -15 16.9kΩ 60kΩ -10 13kΩ 47.3kΩ -5 10.1kΩ 38.4kΩ 0 7.8kΩ 30kΩ +5 6.2kΩ 24.1kΩ +10 4.9kΩ 19.5kΩ +15 3.9kΩ 15.9kΩ +20 3.

- Page 25Micom Circuit description 25�

- Page 26Compressor 12-1 INFORMATION OF LINEAR COMPRESSOR The information tag provides compressor model, refrigerant, serial number and safety approval Compressor Label 1. Compressor Model FLB075LBNA Operating Type Series name A : A-Inverter DLF/FA/FB E : E-Inverter Displacement Rated Voltage ex)90=9.0 /stro

- Page 27Compressor To reduce noise level, the piston stroke is slowly increased to full power during start up. Step 1) Start up - Half stroke interval for first 30 seconds. Step 2) Ramp up - Stroke increases every 0.8sec until maximum stroke length is reached (about 3 min, 15 sec) Step 3) CVCF interval - 18

- Page 28Compressor CON201 Time>30sec Power off Disconnect Power ON PCB OK Y& V≒200 Replace drver PCB Comp Ref. FLB075(A-Inverter) Display & sound Refer TEST1 Forced Starting TDC (Full Stroke) Display ON, Buzz 1 time 28

- Page 29Compressor 12-1 Check A Dear is PC board located in the PCB case. The control driver is PC board for the compressor. This step shows the source voltage of the driver PC board. Step 1. Open PCB Cover Step 2. Check Driver PCB * Driver PCB located in machine room. 29�

- Page 30Compressor 12-1 Check B B1. LED blinks once, then repeats (FCT0 Fault: A-Inverter) Blink OFF Blink OFF - Purpose: Detecting motor current and voltage error - Check voltage at point A (Motor Voltage), point B (Motor Current) and Point C (Capacitor Voltage) when compressor is off. - Spec: Points A, B,

- Page 31Compressor 31�

- Page 32Compressor Protection Compressor Y blink 6 times logic Intermittently (Current Trip)check B5 Check B Works N Replace N IPM Check Driver PCB Compressor Y N Replace Damage Compressor Check Repeat N Current trip Reset Y Check Procedure occur? Power Y Compressor Y N Replace Cycle blockage? Doesn’t works

- Page 33Compressor 33�

- Page 34Compressor 34�

- Page 35Compressor 35�

- Page 36Troubleshooting PCB 1. PCB Picture - Main PCB ( P/N : EBR809775**) CON6 CON5 CON4 CON8 CON3 CON7 CON201 CON1 36�

- Page 37Troubleshooting 2. Display PCB ( P/N : EBR790695**) CON101 37�

- Page 38Troubleshooting with Error Display 1. Freezer Sensor Error Symptom Check Point 1. E FS 1. Check for a loose connection 2. Check Sensor Resistance ( P/N EBR809775**) CON7 CON8 CON201 CON6 CON5 CON4 CON1 CON3 CON8 Resistance [Ω] Short 0 CON8 Open OFF 23th pin ~ 24th pin Other Normal CON8 Resistance [Ω

- Page 39Troubleshooting Freezer Sensor Error (E FS) 1 4 Reconnect or Is the Connector disconnected Yes repair the Check the Sensor resistance. or loose between Main PCB and connector Is resistance normal? sensor? Yes 5 Check the Temperature and resistance refer to the table. No problem? CON8 CON8 No Resista

- Page 40Troubleshooting 2. Refrigerator Sensor Error (E rS) Symptom Check Point 1. E rS 1. Check for a loose connection 2. Check Sensor Resistance ( P/N EBR809775**) CON7 CON8 CON201 CON6 CON5 CON4 CON1 CON7 CON3 Resistance [Ω] Short 0 CON7 Open OFF 19th pin ~ 20th pin Other Normal CON7 Resistance [Ω] 19th

- Page 41Troubleshooting Refrigerator Sensor Error (E rS) 1 4 Reconnect or Is the Connector disconnected Yes repair the Check the Sensor resistance. or loose between Main PCB and connector Is resistance normal? sensor? Yes 5 Check the Temperature and resistance refer to the table. No problem? CON7 CON7 No Re

- Page 42Troubleshooting 2. Refrigerator Sensor Error (E r2) Symptom Check Point 1. E r2 1. Check for a loose connection 2. Check Sensor Resistance ( P/N EBR809775**) CON7 CON8 CON201 CON6 CON5 CON4 CON1 CON7 CON3 Resistance [Ω] Short 0 CON7 Open OFF 17th pin ~18th pin Other Normal CON7 Resistance [Ω] 17th p

- Page 43Troubleshooting Refrigerator Sensor Error ( E r2) 1 4 Reconnect or Is the Connector disconnected Yes repair the Check the Sensor resistance. or loose between Main PCB and connector Is resistance normal? sensor? Yes 5 Check the Temperature and resistance refer to the table. No problem? CON7 CON7 No R

- Page 44Troubleshooting 3. Room Temperature Sensor Error Symptom Check Point 1. E rt 1. Check for a loose connection 2. Check Sensor Resistance ( P/N EBR809775**) CON7 CON8 CON201 CON6 CON5 CON4 CON1 CON5 CON3 Resistance [Ω] Short 0 CON5 Open OFF 13th pin ~ 14th pin Other Normal CON5 Resistance [Ω] 13th pin

- Page 45Troubleshooting Room Temperature Sensor Error (E rt) 1 4 Reconnect or Is the Connector disconnected Yes repair the Check the Sensor resistance. or loose between Main PCB and connector Is resistance normal? sensor? Yes 5 Check the Temperature and resistance refer to the table. No problem? CON5 No CON

- Page 46Troubleshooting 4. Icing Sensor Error Symptom Check Point 1. E IS 1. Check for a loose connection 2. Check Sensor Resistance ( P/N EBR809775**) CON7 CON8 CON201 CON6 Ice Maker Connector CON5 CON4 CON1 CON3 CON6 Resistance [Ω] CON6 Short 0 5st pin ~ 12th pin Open OFF Other Normal CON6 Resistance [Ω]

- Page 47Troubleshooting Icing Sensor Error (E IS ) 1 4 Reconnect or Is the Connector disconnected Yes repair the Check the Sensor resistance. or loose between Main PCB and connector Is resistance normal? sensor? Yes 5 Check the Temperature and resistance refer to the table. No problem? CON6 Ice Maker Connec

- Page 485. Defrost Sensor Error Symptom Check Point 1. F dS 1. Check for a loose connection 2. Check Sensor Resistance ( P/N EBR809775**) CON7 CON8 CON201 CON6 CON5 CON4 CON1 CON3 CON8 Resistance [Ω] Short 0 CON8 Open OFF 21th pin ~ 22th pin Other Normal CON8 Resistance [Ω] 21th pin ~ 22th pin 23ºF / -5ºC 3

- Page 49Troubleshooting Icing Sensor Error (F dS) 1 4 Reconnect or Is the Connector disconnected Yes repair the Check the Sensor resistance. or loose between Main PCB and connector Is resistance normal? sensor? Yes 5 Check the Temperature and resistance refer to the table. No problem? CON8 CON8 Resistance [

- Page 50Troubleshooting 6. Defrost Heater Error Symptom Check Point 1. F dH 1. Check the heater disconnect 2. Check the Fuse hire 3. Check Drain stuck 4. Check the PCB output voltage ( P/N EBR809775**) CON7 CON8 CON201 CON6 CON5 CON4 CON1 CON3 CON3 Part Resistance [Ω] FUSE-M 0 Defrost Heater 48~54 Defrost S

- Page 51Troubleshooting Defrost Heater Error ( F dH) 1 4 Input Test 2 Mode Replace the (Push the button 2 times) Replace Check the Door gasket . Yes Door gasket Check the Heater Voltage. NO Main PCB Is door gasket damaged? Is voltage 112~116V? No CON3 2 Change TEST MODE 2 Voltage [V] Check the Defrost contr

- Page 52Troubleshooting 7. Freezer Fan Error (Er FF) Symptom Check Point 1.- E FF 1. Check the air flow 2. Check the Fan Motor 2. Check the PCB Fan motor voltage ( P/N EBR809775**) CON7 CON8 CON201 CON6 CON5 Fan Motor CON4 CON1 CON3 CON8 TEST MODE 1 Voltage [V] CON8 10~12 VDC 9th pin ~ 12th pin CON8 2~4.5 V

- Page 53Troubleshooting Freezer Fan Error (E FF) 4 Check the Fan Motor voltage Is Fan Motor voltage 10~12V? Replace No Main PCB 1 Reset the unit and Input Test1 Mode. CON8 (Push the button 1 time) TEST MODE 1 Voltage [V] CON8 10~12 VDC 9th pin ~ 12th pin Yes 2 5 Check the Fan Motor voltage Open the freezer

- Page 54Troubleshooting 8. Condenser Fan Error (E CF) Symptom Check Point 1.- E CF 1. Check the air flow 2. Check the fan motor and connector 2. Check the PCB Fan motor voltage CON7 CON8 Fan Motor ( P/N EBR809775**) CON201 CON6 CON5 CON4 CON1 CON3 CON8 TEST MODE 1 Voltage [V] CON8 10~12 VDC 11 th pin ~ 16th

- Page 55Troubleshooting Condenser Fan Error ( E CF) 4 Check the Fan Motor voltage Is Fan Motor voltage 10~12V? Replace No Main PCB 1 Reset the unit and Input Test1 Mode. CON8 (Push the button 1 time) TEST MODE 1 Voltage [V] CON8 10~12 VDC 11 th pin ~ 16th pin Yes 2 5 Check the Fan Motor voltage Check the fa

- Page 569. Communication Error (E CO) No. Checking flow Result & SVC Action 1 Check the loose connection 2 Check the Yellow to Blue. 3 Check the Blue to Brown 4 Check the Red to Blue. 5 Check the pin15 to pin18 of CON5 6 Check the pin15 to pin17 of CON5 56�

- Page 5710. Ice Maker Motor Error (E It) Symptom Check Point 1. E It 1. Check for a loose connection 2. Check Sensor Resistance ( P/N EBR809775**) CON7 CON8 CON201 CON6 CON5 CON4 CON1 CON3 CON6 Housing Resistance [Ω] CON6 374~456 7th pin ~ 8th pin CON6 374~456 9th pin ~ 10th pin 57

- Page 58Ice Maker Motor Error ( E It) 1 3 Disconnect housing of Main PCB Explain to Change the Yes And check resistance between ICE Maker Input Ice Maker test mode(Push customer No Pink and blue wires. Is Motor Unit The ice maker test button),check resistance 374~456Ω? The Ice Tray,Ice maker motor Rotate? W

- Page 59Troubleshooting without Error Display 1. Cube mode doesn’t work Symptom Check Point 1. Cube mode 1. Check the loose connection doesn’t work 2. Check the resistance ( P/N EBR809775**) CON7 CON8 CON201 CON6 CON5 CON4 CON1 CON3 Duct Motor Ice Maker Auger Motor 59

- Page 601. Cube mode doesn’t work Result ICE / Water INSPECTION POINT LEVER S/W ICE/Water Lever SW Pushing 0~2V CON6 19th pin ~ 20th pin Not Pushing 3.5~5V Duct Motor Pushing 9~12V CON6 23th pin ~ 24th pin Not Pushing 0~2V Motor Type Resistance [Ω] Auger Motor Pushing 112~115V Auger Motor 33~ 37 CON3 4th pi

- Page 614 Check the resistance value. 1. Cube mode doesn’t work Replace Is Dispenser Motor resistance No Geared Motor 9.9 ~ 12.1Ω? Cube mode doesn't work 1 Check the loose connection Dispenser Motor 2 Change the No PCB Resistance [Ω] Check the voltage. (while pushing the lever S/W) Dispenser Motor 9.9 ~ 12.

- Page 622. Crush mode doesn’t work Symptom Check Point 1. Crush mode 1. Check the loose connection doesn’t work 2. Check the resistance ( P/N EBR809775**) CON7 CON8 CON201 CON6 CON5 CON4 CON1 CON3 Duct Motor Ice Maker Auger Motor 62

- Page 632. Crush mode doesn’t work Result ICE / Water INSPECTION POINT LEVER S/W ICE/Water Lever SW Pushing 0~2V CON6 19th pin ~ 20th pin Not Pushing 3.5~5V Duct Motor Pushing 9~12V CON6 23th pin ~ 24th pin Not Pushing 0~2V Motor Type Resistance [Ω] Auger Motor Pushing 112~115V Auger Motor 23~27 CON3 4th pi

- Page 642. Crush mode doesn’t work 4 Check the resistance value. Replace Is Dispenser Motor resistance No Geared Motor 9.9 ~ 12.1Ω? Crush mode doesn't work 1 Check the loose connection Dispenser Motor 2 Change the No PCB Resistance [Ω] Check the voltage. (while pushing the lever S/W) Dispenser Motor 9.9 ~ 1

- Page 653. Water mode doesn’t work Symptom Check Point 1. Water mode 1. Check the loose connection doesn’t work 2. Check the resistance valve Ground (BL) (1) (2) (3) (4) Water Valve(RD) Pilot Valve (GY) CON3 Pilot Valve Water Valve Machine Room Result INSPECTION Water POINT LEVER S/W Water Lever SW Pushing

- Page 66Water mode doesn’t work 1 3 Replace Check the loose connection Check the resistance value. No Water Valve Is Pilot Valve resistance 390~450 Ω? 2 Change the Check the voltage. No PCB (while pushing the lever S/W) Is voltage correct compared with table? Pilot Valve Valve Resistance [Ω] Pilot Valve 390

- Page 674. Refrigerator room led doesn’t work Symptom Check Point 1. Refrigerator room led 1. Check the refrigerator door switch sticky doesn’t work 2. Check the door S/W resistance 3. Check the LED Lamp Door S/W CON5 (R-Door S/W) CON7 (R-LED Supply) R Led Lamp Resistance [Ω] Open Infinity Door S/W Closed 0

- Page 68Refrigerator room lamp doesn’t work 1 4 Change the Change the Check the Freezer door switch. Yes Door S/W Check the LED Lamp voltage. No Door S/W Does it feel sticky? Is it 0~2V? (While door closed) No 2 Yes Change the Check the door S/W resistance. No Door S/W Is it correct compared with table? 5 C

- Page 695. Freezer room led doesn’t work Symptom Check Point 1. Freezer room led 1. Check the freezer door switch sticky doesn’t work 2. Check the door S/W resistance 3. Check the LED Lamp Door S/W CON5 (F-Door S/W) CON8 (F-LED Supply) F Led Lamp Resistance [Ω] Open Infinity Door S/W Closed 0 INSPECTION DOO

- Page 70Freezer room lamp doesn’t work 1 4 Change the Change the Check the Refrigerator door switch. Yes Door S/W No Door S/W Check the LED Lamp voltage. Does it feel sticky? Is it 0~2V? (While door closed) No 2 Yes Change the Check the door S/W resistance. No Door S/W Is it correct compared with table? 5 C

- Page 716. Poor/Over cooling in Fresh food section Symptom Check Point 1. Poor cooling in Fresh 1. Check the sensor resistance food section 2. Check the air flow 3. Check the air Temperature 4. Check the R-Damper motor voltage Duct CON7 CON8 Fan Motor CON6 R1SNR Resistance 5th pin ~ 6th pin [Ω] 23ºF /-5ºC 3

- Page 72Check the 4 Check the air temperature. No Compressor Is it cold? and sealed system Poor cooling in Fresh food section Yes Go to 8 1 Check the sensor resistance. 5 Check the Fan Motor voltage Is Fan Motor voltage 10~12V? Replace No Main PCB CON7 CON8 CON6 R1SNR Resistance [Ω] 5th pin ~ 6th pin TEST M

- Page 737. Poor cooling in Freezer compartment Symptom Check Point 1. Poor cooling in 1. Check the sensor resistance Freezer compartment 2. Check the air flow 3. Check the air Temperature 4.Check the Fan motor sticky 4. Check the Fan motor voltage Duct CON8 Fan Motor CON8 Voltage Resistance TEST MODE 1 [V]

- Page 747) Poor cooling in Freezer compartment Poor cooling in Freezer compartment 1 3 Check the F Check the sensor resistance. No Fan Motor Open the fresh food door and Go to 5 Check the air flow. Windy? CON8 CON8 Resistance 23 th pin ~ 24th pin [Ω] -22ºF / -30ºC 40k -13ºF / -25ºC 30k Yes -4ºF / -20ºC 23k

- Page 756 Check the Fan Motor voltage Is Fan Motor voltage 10~12V? Replace No Main PCB CON8 TEST MODE 1 Voltage [V] CON8 10~12 VDC 9th pin ~ 12th pin Yes 7 Check the Fan Motor voltage Is Fan PWM voltage 2~4.5V ? Replace No Main PCB CON8 TEST MODE 1 Voltage [V] CON8 2~4.5 VDC 9th pin ~ 19th pin No 8 Check th

- Page 76Troubleshooting 1. COMP operation error 1 2 1.Open the PWB COVER When the COMP 3 2.Check the number of LED blinks is normal, it will (Refer to the next page for resolution by number of LED not blink blinks 1.Open the BACK COVER 4 3.Check the COMP connector voltage (Measure without pulling the HOUSIN

- Page 77Troubleshooting 2. Resolution by number of LED blinks No. LED operating condition Cause Service guide LED blinking 1 time repeatedly 1. After resetting the power check PCB part normal operation 1 defect 2. When the same symptom occurs (MICOM) again after taking action for 1, Blink -Off-Blink-Off-Bli

- Page 78Troubleshooting 3. Reference 1) TEST MODE and Removing TPA 1.How to make TEST MODE If you push the test button on the Main PCB, the refrigerator will be enter the TEST MODE * 1 time :Comp / Damper / All FAN on * 2 times :Forced defrost mode (All things displayed) (22 22 displayed) Main PWB 2. How to

- Page 79Troubleshooting 2) TEMPERATRUE CHART - FRZ AND ICING SENSOR TEMP RESISTANCE VOLTAGE -39°F( -40°C) 73.29Ω 4.09 V -30°F(-35°C) 53.63Ω 3.84 V -21°F(-30°C) 39.66Ω 3.55 V -13°F( -25°C) 29.62Ω 3.23 V -4°F(-20°C) 22.33Ω 2.89 V 5°F(-15°C) 16.99Ω 2.56 V 14°F( -10°C) 13.05Ω 2.23 V 23°F( -5°C) 10.1Ω 1.92 V 32°

- Page 80Troubleshooting 3) TEMPERATRUE CHART - REF AND DEF SENSOR TEMP RESISTANCE VOLTAGE -39°F( -40°C) 225.1Ω 4.48 V -30°F(-35°C) 169.8Ω 4.33 V -21°F(-30°C) 129.3Ω 4.16 V -13°F( -25°C) 99.3Ω 3.95 V -4°F(-20°C) 76.96Ω 3.734 V 5°F(-15°C) 60.13Ω 3.487 V 14°F( -10°C) 47.34Ω 3.22 V 23°F( -5°C) 37.55Ω 2.95 V 32°

- Page 81Troubleshooting 4) TEMPERATRUE CHART - AMBIENT SENSOR TEMP RESISTANCE VOLTAGE -39°F( -40°C) 225.1Ω 4.79 V -30°F(-35°C) 169.8Ω 4.72 V -21°F(-30°C) 129.3Ω 4.64 V -13°F( -25°C) 99.3Ω 4.54 V -4°F(-20°C) 76.96Ω 4.43 V 5°F(-15°C) 60.13Ω 4.29 V 14°F( -10°C) 47.34Ω 4.13 V 23°F( -5°C) 37.55Ω 3.95 V 32°F( 0°C

- Page 82How to disassemble and assemble 1. DOOR (4) Lift up the freezer door 1 in arrow direction and disconnect 1) Disconnect water supply tube 2 in the lower part of the door from the lower hinge 2 . Don’t pull the door forward. freezer door. Pull the water supply tube forward while pressing on the coupli

- Page 83How to disassemble and assemble 3-10 DISPENSER 3-12 ICE BUTTON ASSEMBLY 1) Remove the 1 screw holding the lever. 2) Remove the spring from the hook. 3) Push and pull on the tab to remove. 1) Pull out the drain 2) Use these 2 holes to pull out the bottom Button Lever 3-13 WATER BUTTON ASSMEBLY 3) If

- Page 84How to disassemble and assemble 4.WATER VALVE DISASSEMBLY METHOD 1)Turn off the power of the refrigerator (pull out the plug). 4)Separate the Mechanical Cover and Valve Screw. Open the FREEZER and REFRIGERATOR Door and disassemble the Lower Cover. Mechanical Cover 5)Separate the housing and pull out

- Page 85How to disassemble and assemble 6. ICEMAKER DISASSEMBLY METHOD 2) Hold the front of the Cover,TV and Pull it out completely. Note :to disassemble the icemaker, separate Motor, AC from the door first. 1 disassemble Ice bin and cover. Cover 3) Loosen 1 Screw on the Water Tank. Ice bin 2 Separate the M

- Page 86How to disassemble/reassemble the refrigerator home bar How to disassemble/reassemble the refrigerator home bar 1. Family home bar model 1-2. The Method to disassemble the Home Bar button 1-1. How to disassemble the home bar 1. Separate the H/Bar Gasket adjacent to the Holder,Lever,and then unscrew

- Page 87How to adjust the refrigerator door level difference How to adjust the refrigerator door level How to adjust the door level difference difference * It may be unleveled concerning installed condition of the floor. 1. When the refrigerator door is low 1. Open the door. 1. When the bottom part of refri

- Page 88Heavy Repair Method of Refrigerator by Application of Refrigerant Heavy Repair Method of Refrigerator by Application of Refrigerant 1. Heavy Repair SVC Method For the heaver repair of R134a type of refrigerator, perform work according to following SVC method. 1-1. Return of Refrigerator Refrigerant

- Page 89Heavy Repair Method of Refrigerator by Application of Refrigerant 1-2. Return of Remained Refrigerant Required equipment: Pinch pliers, hose for refrigerant recovery, vacuum pump If refrigerant returntime of 7 minutes has passed, connect a vacuum pump at the ends of a refrigerant returnhose outdoor.

- Page 90Heavy Repair Method of Refrigerator by Application of Refrigerant 1-4. Charging Tube Connection Step Required equipment: Charging tube, simple welding machine Remove a charging pipe to recharge R134a refrigerant after completing work, and then connect a charging tube with welding Suction Pipe Chargi

- Page 91Heavy Repair Method of Refrigerator by Application of Refrigerant 1-6. Refrigerant Charging Required equipment: Bombe, R134-a refrigerant (Energy Star, Al spiral condenser model : 165g / DOE, Fe wire condenser model: 175g) • Firstly remove fire appliances and heating source for performing work when

- Page 92#EV# EXPLODED VIEW FREEZER DOOR 131C 600A 200A 203A 405H 131D 282H 612A 282G 280A 113F 113E 606A 244A 241G 208A 241J 92�

- Page 93#EV# REFRIGERATOR DOOR (For models LSXC22326* / LSXC22336*) 230A 231A 241A 233A 212K 212G 244A 212J 241D 212K 241H�

- Page 94#EV# REFRIGERATOR DOOR (For models LSXC22386* ) 241H 241D 231B 231A 271D 241F 233A 212G 212K 241B 244F 212J 212K 241A 93�

- Page 95#EV# FREEZER COMPARTMENT 120E 625A 312C 158C 903E 281A 271B 404A 271A 619A 330B 329A 405A 405D 332A 903G 405G 135J 301A 316B 149A 149C 332B 128C 128D 128E 161C 128F 281G 136A 135D 319B 154C 136B 94�

- Page 96#EV# REFRIGERATOR COMPARTMENT 625A 281B 158A 271B 611E 271C 903D 120B 140A 120A 120D 154B 136C 128G 128H 611B 621B 616K 281H 154A 615A 610E 623A 627B 627C 151A 243E 95�

- Page 97#EV# MACHINE COMPARTMENT 103B 411A 501F 502B 410G 410H 308A 501A 304A 316A 307A 105A 314A 314A 317A 319C 318A 404B 405C 405F 503A 329C 319E 312A 319A 315A 96�

- Page 98MFL62215932 May, 201�