Traulsen Page 6

Workshop Manuals

-5-

VI. CONDENSER COIL

VI. a-REPLACEMENT INSTRUCTIONS:

Disconnect the electrical power to the

machine and follow lockout/tag out procedures.

This procedure requires the use of re-

frigerants, be certain the work area is well ventilat-

ed. Safety goggles and gloves shall be worn since

refrigerants may cause burns to the skin.

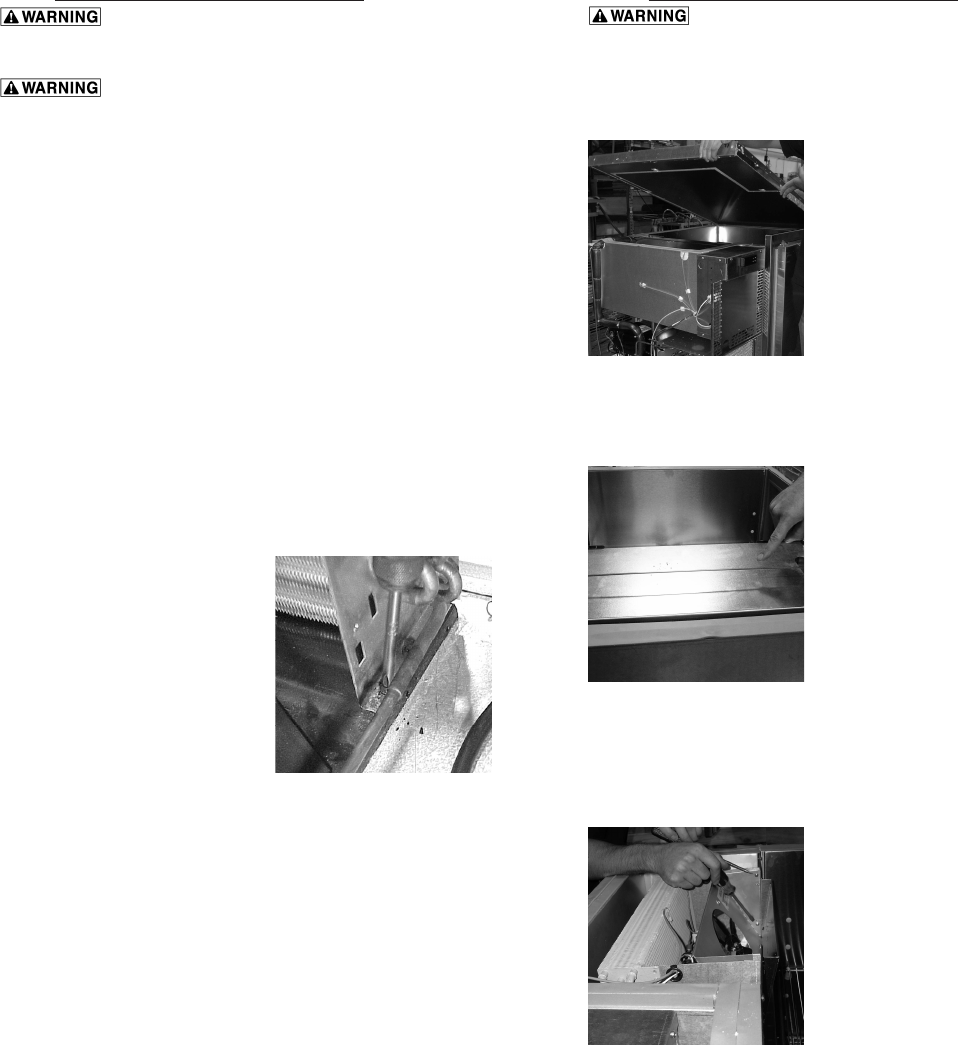

Step 1: Remove the louver assembly as outlined in

section III. a.

Step 2: Recover the refrigerant in the system following

the current EPA Guidelines for refrigerant recovery.

NOTE: The use of reclaiming equipment is required.

Step 3: Disconnect the input and output lines to the

condenser coil at the soldered joints closest to the

condenser.

Step 4: Remove the four (4) screws which secure the

condenser coil to the mounting brackets (see Illustration

VI. 1).

Step 5: Remove the condenser coil.

Step 6: Reverse the procedure to install the new con-

denser coil.

Step 7: Install a new drier.

Step 8: Charge the refrigeration system as outlined un-

der “CHARGING SYSTEM” in “SERVICE PROCEDURES

AND ADJUSTMENTS”.

Step 9: Reconnect power to the unit.

Step 10: Reset the microprocessor control defrost time

settings to the correct time of the day.

Illustration VI. 1

VII. EVAPORATOR FAN

VII. a-REPLACEMENT INSTRUCTIONS:

Disconnect the electrical power to the

machine and follow lockout/tag out procedures.

See section III. b. for removal of evaporator housing

cover.

Remove the steel evaporator fan assembly retaining pin

from the evaporator housing.

Remove evaporator fan housing amounting screws to

allow for removal of entire evaporator fan motor as-

sembly.

Disconnect electrical.

Illustration VII. 3

Illustration VII. 2

Illustration VII. 1

Contents Summary of Traulsen

- Page 1Traulsen Refrigeration SERVICE MANUAL Instructions For The Troubleshooting And Repair Of Traulsen Full-Size Undercounter Refrigerators and Freezers TU044HT, TU072HT & TU100HT Refrigerator Models TU044LT & TU072LT Freezer Models This manual is prepared for the use of trained Authorized Traulsen Servi

- Page 2TABLE OF CONTENTS I. THE SERIAL TAG Page 1 V. CONDENSER FAN MOTOR OR BLADE Page 4 II. GENERAL INFORMATION Page 2 VI. CONDENSER COIL Page 5 a-Introduction Page 2 VII. EVAPORATOR FAN Page 5 b-Model Designations Page 2 VIII. COMPRESSOR Page 6 c-Wiring Diagram Page 2 IX. WIRING DIAGRAM Page 7 d-Installa

- Page 3II. GENERAL INFORMATION II. a-INTRODUCTION: II. f-TOOL REQUIREMENTS (cont’d): This manual applies to the following models only: ● Refrigeration Guage Manifold ● Refrigeration Reclaiming Equipment TU Series Full-Size Undercounter Refrigerators ● Acetylene Torch TU044HT, TU072HT & TU100HT ● Anti-Stati

- Page 4II. GENERAL INFORMATION (cont’d) II. i-THE MICROPROCESSOR CONTROL: II. m-SPECIFICATIONS-REFRIGERATOR: For detailed information on replacement, repair or adjustment of the INTELA-TRAUL® microprocessor control please refer to it’s TU044HT TU072HT TU100HT manual, form number TR35705 or contact our Serv

- Page 5III. SERVICE ACCESS (cont’d) V. CONDENSER FAN MOTOR OR BLADE III. a-SYSTEM(cont’d): V. a-REPLACEMENT INSTRUCTIONS: To gain full access to the refrigeration system from the Disconnect the electrical power to the machine side, remove the side cover by removing the screws. and follow lockout/tag out pr

- Page 6VI. CONDENSER COIL VII. EVAPORATOR FAN VI. a-REPLACEMENT INSTRUCTIONS: VII. a-REPLACEMENT INSTRUCTIONS: Disconnect the electrical power to the Disconnect the electrical power to the machine and follow lockout/tag out procedures. machine and follow lockout/tag out procedures. This procedure requires

- Page 7VIII. COMPRESSOR VIII. a-COMPRESSOR: Disconnect the electrical power to the machine and follow lockout/tag out procedures. This procedure requires the use of re- frigerants, be certain the work area is well ventilated. Safety goggles and gloves shall be worn since refrig- erants may cause burns to t

- Page 8IX. WIRING DIAGRAM NOTE: Refer to the wiring diagram below (applies to refrigerators and freezers units) for any service work performed by a qualified technician. -7-�

- Page 9X. SERVICE PROCEDURES & ADJUSTMENTS Certain procedures in this section require electrical test or measurements while power is applied to the machine. Excercise extreme caution at all times. If test points are not easily accessible, disconnect power, attach test equipment and reapply power to test. X

- Page 10X. SERVICE PROCEDURES & ADJUSTMENTS (cont’d) Certain procedures in this section require electrical test or measurements while power is applied to the machine. Excercise extreme caution at all times. If test points are not easily accessible, disconnect power, attach test equipment and reapply power t

- Page 11X. PROCEDURES & ADJ. (cont’d) XI. ELECTRICAL OPERATION Certain procedures in this section re- XI. a-NORMAL OPERATION: quire electrical test or measurements while power is 1. Conditions applied to the machine. Excercise extreme caution a) Unit connected to correct voltage (check using a volt me- at a

- Page 12XI. ELECTRICAL OPERATION (cont’d) XI. c-COMPONENT FUNCTION: COMPONENT FUNCTION 1. Compressor Pumps refrigerant thru refrigeration system components and compresses the low pressure vapor into high pressure vapor. 2. Evaporator Fan Draws air across condenser coil to aid in removing heat from the refri

- Page 13XII. TROUBLESHOOTING Certain procedures in this section require electrical and refrigeration system test or measurements while power is applied to the machine, exercise extreme caution at all times. If test points are not easily accessible, disconnect power, attach test equipment and reapply power t

- Page 14XIII. SERVICE PARTS LIST NOTE: Part numbers listed are for standard products as currently manufactured. For products manufactured as other than standard, please contact the factory with model and serial number of unit in question. ITEM DESCRIPTION PART NUMBER Casters All Models 6” Adjustable - No Lo

- Page 15XIV. SERVICE ASSISTANCE XIV. a-SERVICE INFORMATION: NOTE: Before calling for service, please check the following: Is the electrical cord plugged in? Is the fuse OK or circuit breaker on? Clean condenser coil Is the power switch on? Reset microprocessor control values to factory defaults. If after ch

- Page 16HOURS OF OPERATION: Monday thru Friday 7:30 am - 4:30 pm CST Traulsen 4401 Blue Moud Road Fort Worth, TX 76106 Phone (800) 825-8220 Fax (817) 740-6757 Website: www.traulsen.com Quality Refrigeration © 2009 Traulsen - All Rights Reserved