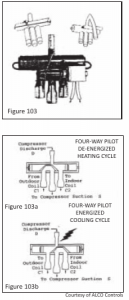

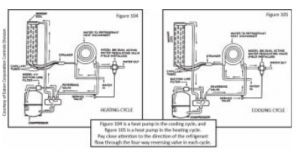

Reversing valves are used in heat pumps. It is a four-port solenoid valve with one port connected to the compressor suction tube, one port to the discharge tube, one to the indoor coil, and one port connected to the outside coil. (See figs. 103a and b, 104, and 105.)

Solenoid valves become inoperative due to either electrical or mechanical malfunction. If due to an internal short or disconnection a valve becomes incapable of creating enough magnetism to lift the plunger, the coil will have to be replaced. (Remove the screws holding the coil.) Any disconnection in the coil can be detected when the two coil terminals are touched with the two ohmmeter probes. (Set scale on RX1.) If the valve develops a leaky seat causing the needle to stick or chatter, the valve must be replaced. Most solenoid valves will not operate unless they are in a vertical position and right side up. The voltage rating must be compatible with the replacement valve.

When this solenid valve is de-energized, the unit is in the heating cycle which means that the indoor coil acts as a condenser and the outside coil acts as an evaporator. (See fig. 103a.)

The discharge gas flows through ports D and C2, making the indoor coil the condenser.

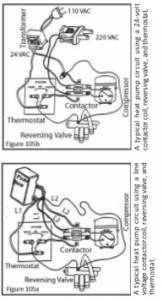

The suction gas flows from the outdoor coil (evaporator) through reversing ports C1 to S and back to the compressor. When the coil is energized (see fig. 103b), the unit changes over to the cooling cycle with the discharge gas flowing through reversing valve ports D to C1, making the outdoor coil the condenser, and the suction gas flows through port C2 to S, thus making the indoor coil the evaporator. Figure 105a shows a typical wiring of a reversing valve in a heat pump that uses line voltage. Figure 105b shows a typical heat circuit using a 24 V contactor, reversing valve, and thermostat.