Since they are hermetically sealed, resulting in an improved drive method (the motor and compressor being located in a common enclosure), rotary compressors are presently manufactured in large quantities, particularly in fractional-tonnage applications. By definition, a hermetic compressor is one in which the electric motor and compressor are contained within the same pressure vessel, with the motor shaft integral with the compressor crankshaft. The motor is in constant contact with the refrigerant.

In operation, the rotary-type compressor performs the same function as the reciprocating compressor. The compression of the gas establishes a pressure difference in the system to create a flow of refrigerant from one part of the system to the other. The rotary type compressor, however, employs a slightly different method of accomplishing the compression of the gas. The rotary compressor compresses gas because of the movement of the rotor in relation to the pump chamber.

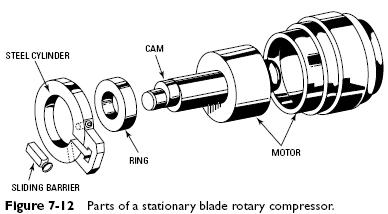

The two types or configurations of rotary compressors are the stationary-blade rotary compressor and the rotating blade rotary compressor. Figure 7-12 is an example of the stationary blade type. Note how the sliding barrier operates inside the steel cylinder.

The only moving parts in a stationary blade rotary compressor are a steel ring, an eccentric or cam, and a sliding barrier. Figure 7-13 labels the parts of this type of operation, while Figure 7-14 shows how the rotation of the off-center cam compresses the gas refrigerant in the cylinder of the rotary compressor. The cam is rotated by an electric motor. As the cam spins, it carries the ring with it. The ring rolls on its outer rim around the wall of the cylinder.

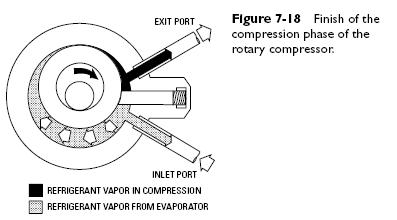

The gas must have a pathway to be brought into the chamber. Note that in Figure 7-15 the vapor comes in from the evaporator and goes out to the condenser through holes that have been drilled in the compressor frame. Note that the gas is compressed by an offset rotating ring. Figure 7-16 shows how the refrigerant vapor in the compressor is brought from the evaporator as the exit port is opening. When the compressor starts to draw the vapor from the evaporator, the barrier is held against the ring by a spring. This barrier separates the intake and exhaust ports. As the ring rolls around the cylinder, it compresses the gas and passes it on to the condenser (see Figure 7-17). The finish of the compression portion of the stroke or operation is shown in Figure 7-18. The ring rotates around the cylinder wall. It is held in place by the spring tension of the barrier’s spring and the pressure of the cam being driven by the

electric motor.

This type of compressor is not used as much as the reciprocating hermetic type of compressor, because there are some problems with lubrication. Better seals are still being developed. This type of compressor is used in some home refrigerators and air conditioners. However, they have been known to become overworked in very hot climates and have been replaced by the reciprocating type.

The other type of rotary compressor is the rotating blade type (see Figure 7-19). This type has a roller centered on a shaft that is eccentric to the center of the cylinder. Usually, there are two spring-loaded roller blades, mounted 180◦ apart. The blades sweep the sides of the cylinder. The roller is so mounted that it touches the cylinder at a point between the intake and discharge ports. As the roller rotates, vapor moves into the cylinder through the intake port and is trapped in a space between the cylinder wall, the blade, and the point of contact between the roller and the cylinder. Vapor is compressed as the next blade passes the contact point and the vapor space becomes smaller and smaller. When the vapor has been compressed to a certain pressure, it leaves by way of the exhaust port on its way to the condenser. This type of rotary compressor, like the stationary blade model, requires extremely close tolerances.

Some manufacturers make rotary-blade compressors for commercial applications. They are used primarily with ammonia. Thus, there is no copper or copper alloy tubing or parts. Most of the ammonia tubing and working metal is stainless steel.